12kW Hydro Miner Radiator Guide for Antminer Cooling

2025年10月15日

Cryptocurrency mining racks push a lot of heat — especially modern Antminer-class ASICs that consume kilowatts per rig. If you’re moving from air-cooled cabinets to liquid/hydro cooling, the radiator is the unsung hero: it takes the heat the miners generate and dumps it to the environment efficiently, quietly, and with far less dust and noise. This article explains what a hydro miner radiator is, why a 12kW radiator matters for ASIC farms, how to size and install one, and practical tips to keep it running reliably.

What is a Hydro Miner Radiator (Antminer Radiator)?

A hydro miner radiator is a purpose-built heat exchanger that cools the liquid circulating through an ASIC miner’s closed-loop cooling system. Warm coolant from the miners flows into the radiator, air (from fans) removes heat from the coolant, and cooled liquid returns to the miners. Radiators for mining are scaled for sustained thermal loads (measured in kW), rugged construction, and high airflow to match dense mining deployments.

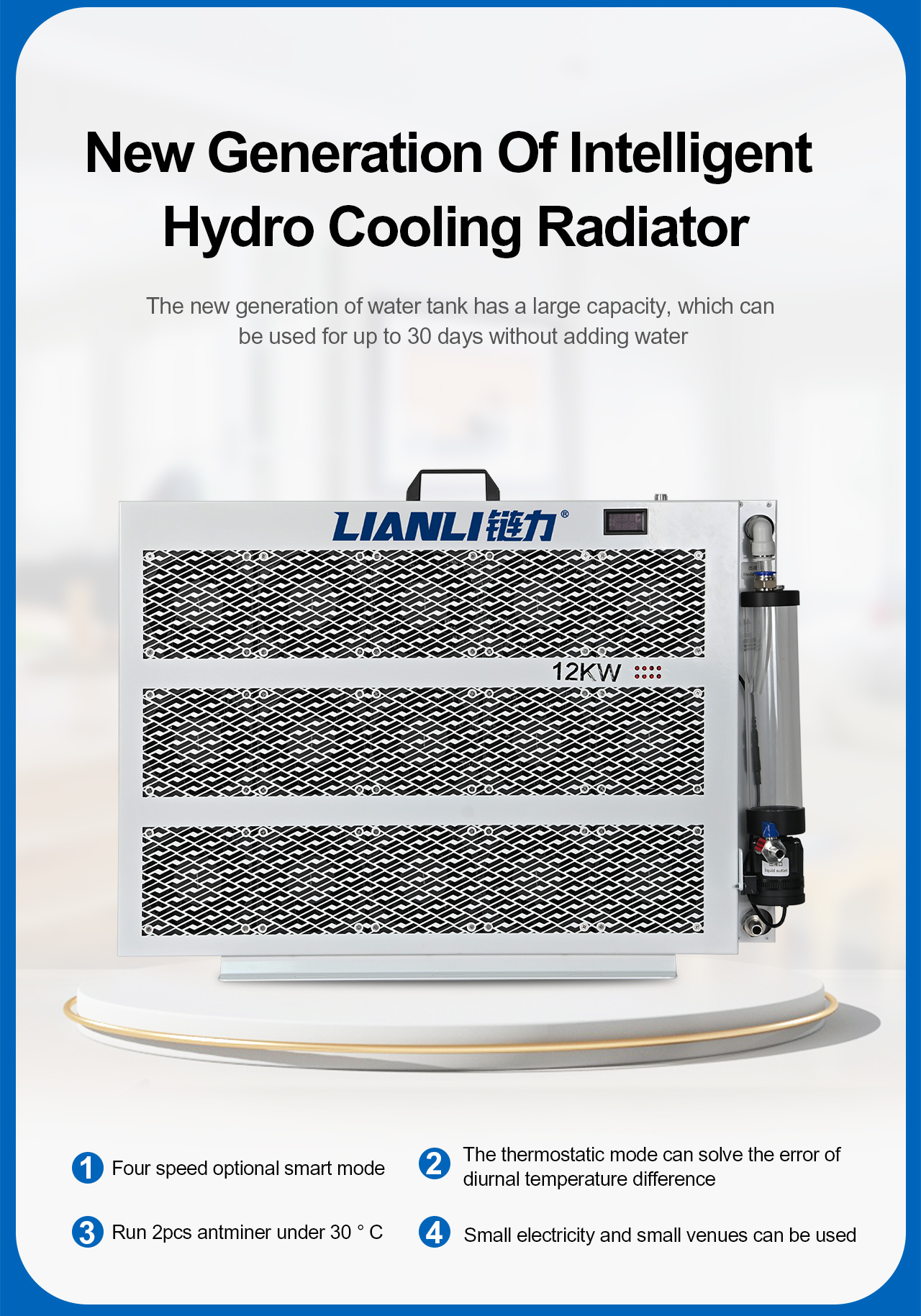

Why choose a 12KW Hydro Cooling Radiator?

A 12kW radiator is sized to continuously dissipate roughly 12,000 watts of heat — suitable for small to medium racks of high-power Antminers or several mid-power ASICs running in tandem. Benefits include:

Lower operating noise: Fans can run at lower RPMs for the same heat removal versus many small air-conditioned cabinets.

Better temperature stability: Liquid’s thermal mass smooths spikes and improves component longevity.

Space efficiency: One radiator handling multiple miners reduces the need for massive air-handling infrastructure.

Scalability: Multiple 12 kW radiators can be paralleled for redundancy and capacity.

Sizing basics — flow rate and delta-T

To size pumps and plumbing, you need an expected coolant temperature rise (delta-T) through the miner loop. Using water’s specific heat (~4.186 kJ/kg·K):

For 12kW with a 5°C delta-T, required flow ≈ 34.4 L/min (≈ 9.1 GPM).

For 12kW with a 10°C delta-T, required flow ≈ 17.2 L/min (≈ 4.5 GPM).

Lower delta-T demands higher flow and larger pumps; higher delta-T reduces flow but increases component temperatures. A common practical target is 5–8°C for stable temperatures without oversized pumps.

Key radiator design features to look for

Core material: Copper cores with brass tanks give the best thermal conductivity and corrosion resistance; aluminum cores are lighter and cheaper but need corrosion inhibitors.

Fin density (FPI): Higher fins per inch increase heat transfer but need more airflow. Mining radiators often use moderate FPI to balance fan power and cooling.

Fan configuration: High static-pressure axial fans or multiple stacked fans to achieve recommended airflow at the radiator’s pressure drop. PWM control allows quiet, efficient operation.

Pressure rating & ports: G1/4 or 3/8" BSP/NPT ports are common. Ensure port sizes match your fittings; choose a radiator rated for system pressure and compatible coolant.

Redundancy options: Dual-loop or parallel radiator config allows maintenance with no downtime.

Installation & plumbing tips

Pump choice: Match pump curve to your flow and system head (include tubing, fittings, miners’ waterblocks, and radiator). For a 12 kW loop with moderate plumbing and a 5–10°C delta-T, choose a pump that can deliver the calculated flow at ~1–3 meters of head depending on loop complexity.

Use proper fittings: Compression fittings or push-to-connect fittings rated for your coolant and pressure minimize leaks. Avoid crude hose clamps on soft tubing for permanent installs.

Fill and bleed carefully: Tilt racks and use bleed valves to evacuate air pockets—air reduces heat transfer and can cavitate pumps.

Coolant selection: Deionized water plus corrosion inhibitor is common; for low-freeze or higher temp stability, use propylene-glycol mixes (which reduce thermal performance vs. pure water).

Filtration: A fine mesh or inline filter ahead of the pump protects pumps and waterblocks from debris.

Monitoring, maintenance, and safety

Temperature sensors: Place sensors on the coolant inlet and outlet of both miners and radiator. Monitor delta-T and set alarms for unexpected rises.

Regular checks: Monthly visual inspection, quarterly coolant checks for pH and inhibitor level, and replace coolant annually or per manufacturer guidance.

Fault handling: Implement automatic shutdown triggers for pump failure, low flow, or over-temperature to protect ASICs.

Leak mitigation: Use drip trays and moisture sensors in racks; design the room drainage and electrical layout with potential leaks in mind.

Practical deployment scenarios

Edge/micro-farm: One 12kW radiator cooling a 3–6-rig bay of modern Antminers can be compact and quiet for residential or small industrial locations (subject to local regulations).

Warehouse scale: Multiple 12 kW radiators in parallel provide redundancy and modular scaling—grow capacity without large single points of failure.

Hybrid systems: Use radiator arrays plus free cooling (air economizers) seasonally to reduce electricity for fans or chiller use.

Quick buying checklist

Confirm continuous thermal rating (12 kW at X°C ambient).

Check materials and corrosion warranty.

Verify port sizes and mounting options.

Ensure the vendor supplies or recommends compatible fans and pump curves.

Ask about modular expansion and serviceability.

Final note

A well-specified 12kW hydro miner radiator changes the economics of a mining deployment — lowering noise, improving hash-stability, and simplifying thermal management. Consider starting with clear targets (desired delta-T, footprint, redundancy), and choose components (pump, fittings, coolant, and radiator) to match those targets. For a real-world example of premium case and cooling-focused designs, check offerings from established hardware makers such as Lian Li.

FAQ About Hydro Miner Radiator

What is an Antminer radiator and how does it work?

An Antminer radiator is a specialized heat exchanger used to cool liquid-cooled Antminer mining machines. It transfers heat from the circulating coolant to the air, helping maintain stable chip temperatures, reduce noise, and improve mining efficiency. Proper radiator sizing and airflow are essential for optimal performance and equipment longevity.

Why choose a hydro cooling radiator for ASIC miners?

A hydro cooling radiator for ASIC miners offers better thermal performance than traditional air cooling. It removes heat more efficiently, supports higher hashrates, reduces dust buildup, and minimizes noise. This setup is ideal for large-scale mining farms or environments where stable temperatures and low maintenance are priorities.

How much heat can a 12kW hydro miner radiator handle?

A 12kW hydro miner radiator can dissipate approximately 12,000 watts of heat continuously — enough to cool several high-power ASIC miners or multiple Antminer rigs. When paired with the right pump and coolant flow rate, it maintains optimal operating temperatures and prevents thermal throttling during intensive mining sessions.

previous page

previous page

Recommended news

LianLi welcomes visitors to Booth TB09b at iTherM 2025. discover advanced liquid cooling solutions for AI, HPC, and next-generation data centers.

Looking for a crypto mining container for sale? Compare crypto mining containers, cooling types, capacity, and real deployment tips. Find the best crypto mining containers for sale for mining farms in 2025.